Best Pressure-Sensitive Tapes for the Aerospace Industry

Pressure-sensitive tapes play a vital role in the aerospace industry, offering various benefits such as bonding, sealing, insulation, protection, and surface finishing. These tapes are designed to adhere to surfaces when light pressure is applied and provide reliable performance in demanding aerospace environments.

When it comes to selecting the best pressure-sensitive tapes for the aerospace industry, certain factors need to be considered, including temperature resistance, chemical resistance, durability, adhesion strength, and compliance with industry regulations. While specific tape recommendations should be obtained from aerospace manufacturing experts, here are a few commonly used types of pressure-sensitive tapes in the aerospace industry:

High-Temperature Tapes: Aerospace applications often involve exposure to high temperatures. Therefore, pressure-sensitive tapes with excellent heat resistance are essential. These tapes can withstand extreme temperatures and maintain their adhesive properties, ensuring secure bonding in engine components, thermal insulation, and other critical areas.

Flame-Retardant Tapes: Safety is paramount in the aerospace industry, and flame-retardant tapes are utilized to enhance fire resistance. These tapes are designed to self-extinguish when exposed to flames, helping to prevent the spread of fire and protect sensitive equipment and wiring.

Anti-Corrosion Tapes: Aerospace manufacturing often involves materials susceptible to corrosion. Anti-corrosion tapes provide a protective barrier against moisture, chemicals, and other corrosive elements, safeguarding critical components and extending their lifespan.

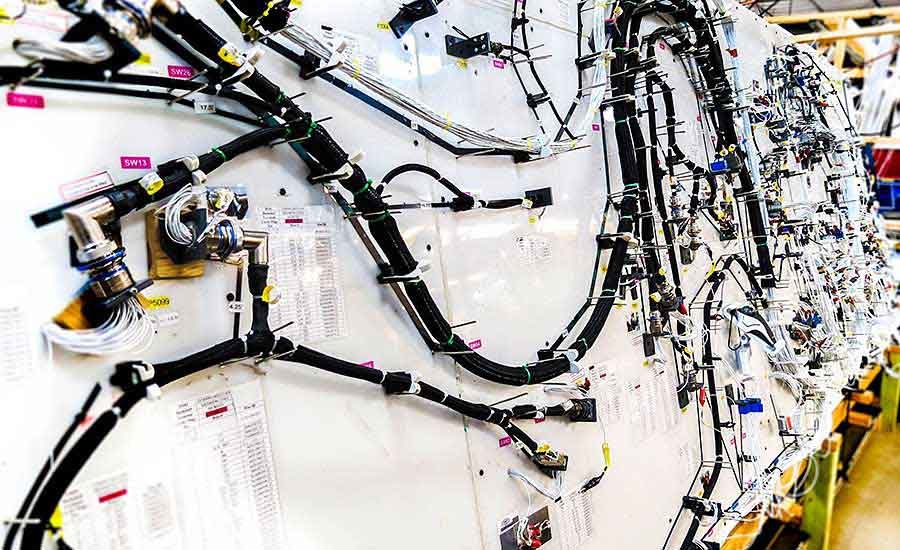

Electrical Insulation Tapes: Electrical systems in aerospace applications require reliable insulation. Electrical insulation tapes offer excellent dielectric properties, preventing electrical current leakage and ensuring proper insulation of wires, cables, and connectors.

Composite Bonding Tapes: In aerospace manufacturing, lightweight composite materials are widely used. Composite bonding tapes provide high-strength adhesive properties, enabling efficient bonding of composite structures, such as aircraft panels, without the need for mechanical fasteners.

It's important to note that specific tape requirements may vary depending on the application and regulatory standards. Therefore, it is recommended to consult with aerospace manufacturing experts or tape suppliers who have in-depth knowledge of the industry's requirements and can provide tailored recommendations.

In conclusion, pressure-sensitive tapes play a crucial role in the aerospace industry, providing bonding, sealing, insulation, and protection. Selecting the best tapes involves considering factors such as temperature resistance, chemical resistance, durability, and compliance with industry regulations. Consulting with aerospace manufacturing experts or tape suppliers such as ATS is essential to identify the most suitable tapes for specific aerospace applications.