What Are Pressure-Sensitive Adhesives?

Pressure-sensitive adhesives help to ensure that tape can bond with the slightest pressure. That being said, it is the combination of various properties that helps to make it as effective as possible. If you want to find out more about pressure-sensitive adhesives or if you want to find out how pressure-sensitive tape works, then take a look below.

What is a Pressure-Sensitive Adhesive?

Pressure-sensitive adhesive is predominantly used in the industrial sector. What makes the adhesive so unique is its very special formulation, as it helps to combine viscosity with elasticity. This flexibility means that it has the potential to adhere well to various surfaces, while having the ability to go solid and rigid, with a high level of cohesion. Natural rubber can easily be added as it has very strong adhesion purposes. A lot of this comes down to the inclusion of resin.

Adhesive tape on rubber is applied when covering painting work or sealing boxes. If adhesive tape has to stick for a very long period of time, or if it has to withstand extreme temperatures and UV light, then most of the time acrylate is used. This can be adjusted to suit the requirements of the application. The best thing about acrylate is that it contains various synthetic polymers, and these can all be tailored to a specific application.

The Science Behind Pressure-Sensitive Adhesives

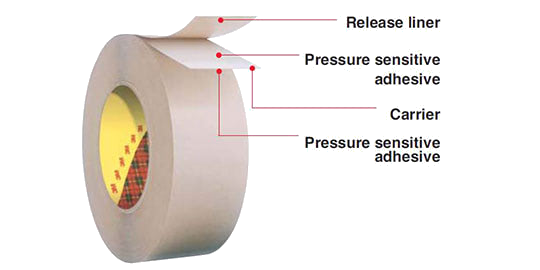

Adhesives like this are very sticky and most of the time they are delivered with a substrate that is made out of plastic, paper, cloth, or metal. You can easily bond two surfaces without the need for heat, water, or solvents. The adhesive system is made out of a polymer chain. This chain consists of large molecules that are interlinked. You also have repeating chains of monomers or smaller molecules. These can be natural or synthetic and depending on the general formation, they can be influenced by a wide range of properties.

Production of Transparent Adhesives

If you want to know how transparent adhesives are made, then you should know that most of the time it starts with natural rubber. This is reduced to small pieces before it is mixed with resin and numerous other materials. It is then homogenized and dissolved. Additional materials are selected according to the requirements of the adhesive. If you want high resistance and the ability to withstand aging, then water-based technology will be used.

Why Does Pressure-Sensitive Tape Bond?

So why is pressure-sensitive tape used and how does it work? Pressure-sensitive tape has so much tackiness, that the pressure alone is enough to bond it to almost any given surface. Although liquid adhesives are often used to cover a surface, it is important to wait until the glue becomes hard. The great thing about pressure-sensitive adhesives is that it helps to solidify the second that you press it down. You don’t need to use a lot of pressure here either. It’s a product that is always at the ready and it is very easy to do the job both reliably and effectively.

So, pressure-sensitive adhesives can be used for a huge number of applications. They are even used in the medical industry, where super-thin applications are required. The biggest use of them would be in the industrial sector however, as two items often need to be fused together, and depending on the application, the use of solvents or liquid adhesive is not always safe, or desirable. Pressure-sensitive tapemay have changed a lot over the years, but the science behind it has helped to bring about a huge range of new applications and uses. It’s now possible to find pressure-sensitive adhesives suited to any purpose.

Where to Buy and Convert Pressure Sensitive Adhesive Tape?

ATS are industry leaders in the conversion, fabrication and distributing of pressure sensitive adhesive tape. We have a full range of tapes (Single Coated Tape, Double Coated Tape, Adhesive Transfer Tape, Transfer Adhesive, Self Wound Tape) in stock that we sell and convert to your specifications.