Water Jet Cutting Services

Partnering for Superior Water Jet Cutting Services

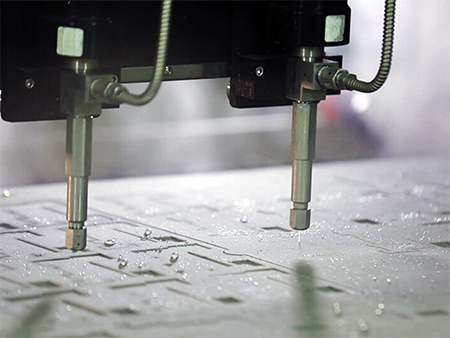

Advanced Technology Supply, Inc. has partnered with Stockwell Elastomerics to provide water jet cutting services to our customers. Our two-axis water jet cutting machinery can accurately slice through thick, low durometer solid or sponge materials without the edge concavity usually associated with steel rule die cutting. Moreover, the edges of thick materials are never scorched, unlike what can occur with some laser burning processes. Water jet cutting can even cut adhesive backings with clean shapes.

Tooling-Free Operations for Enhanced Efficiency

Our water jet cutting operations eliminate the need for tooling.

Therefore, water jet cutting can quicken lead times and save initial costs, particularly if your design is unproven. We can even provide rapid initial prototypes, especially when supplied with electronic drawing files. With our water jet cutting technology, we can cut washers as small as .25 of an inch and other parts as small as .5 of an inch square.

Meeting Diverse Industry Standards with Quick Turnaround

Meeting the needs of multiple industries, from semiconductor to automotive, our ISO compliant water jet cutting operations meet military specifications and can manage all low volume production jobs within a quick turnaround period. We are better suited for low to medium-volume production with this service.

Explore Our Cutting-Edge Water Jet Cutting Solutions

Contact Advanced Technology Supply today to learn more about our water jet cutting operations!

Water Jet Cutting Capabilities

| General Capabilities |

Contract Prototype |

|

| Industry Focus |

Aerospace Automotive Chemical Construction Electrical Electronics Food Processing Machinery Military |

Medical Optical Packaging Pharmaceutical Printing Railroad Recreational Semiconductor |

| Intended Application |

Rubber Gaskets RFI Shielding Metal Masking |

|

| Cutting Method |

Water and Abrasive Material Water Only Laser Cutting |

|

| Cutting Axis | 2-Axis | |

| Characteristics |

Minimum Part Stress No Thermal Distortion or Hardening Reduced Material Cost Through Nesting Reduction or Elimination of Secondary Operations Smooth Finished Edges |

|

| Intended Cutting Material (Metal) |

Alloys Aluminum Armor Brass Bronze Chromium Copper Ferrous Metals Hastelloy Inconel Molybdenum |

Monel Nickel Alloys Non Ferrous Metals Stainless Steel Steel Tantalum Titanium Tungsten Carbide Waspalloy Zirconium |

| Intended Cutting Material (Non-Metal) |

Carbon Fiber Ceramic Concrete Foam Glass Granite Marble |

Plastic Plexiglass Rubber Stone Tile Wood |

| Production Volume | Low Volume | |

| Lead Times Available | Quick Turnaround | |

| Industry Standards |

ISO 9001:2008

Mil Spec Qualify for Veteran Owned Small Business |

|

| File Formats | Images | |

| Cutting Thickness | Up to 1 in. | |

| Cutting Diameter | ¼ in. to 24 in. | |

| Cutting Length | Up to 24 in | |

| Cutting Width | Up to 24 in. | |

| Kerf Kerf is the width of the cut or groove. |

.005 to .020 in. | |

| Tolerance (+/-) | .010 in. |